2024 is Precision Digital’s 50th anniversary. You’re going to see a lot about that in the next 12 months. As I consider how far the line has come since I've been with Precision Digital, I realized it’s a great time for you to notice that as well. Are you utilizing the wide range of new products and solutions you have available from today's Precision Digital?

Are you familiar with our new, modern-looking, and feature rich explosion-proof and intrinsically safe displays? Did you know you can now get a complete solution including a field mount enclosure, light, horn, and front panel pushbutton, with your display? What about our unique loop-powered meters with solid state relays, or the entire line of large display field mount instruments with all the features of the ProVu. There's also the recently enhanced PDW wireless systems, and the incredible ConsoliDator+ multivariable controller, our most powerful device ever.

If you are not using our more recent products regularly, take a look in this email, and the What's New page, and seriously consider what Precision Digital has today you may not know about. Otherwise, you’re only utilizing half of our product line, and potentially missing out on products and solutions you could use in 2024.

Are your panel meters and controllers not working, hard to read, outdated or just need replacing?

Would you like your panel to look more like the ones on the right than the ones on the left in the photo above?

If the answer is YES to these questions, we’ve got plenty of meters and controllers in stock to help!

Precision Digital has a large inventory of finished goods on the shelves and ready to ship. Digital process instruments include 1/8 DIN panel meters, PID temperature controllers, loop-powered meters, level meters, rate/totalizers, batch controllers, Modbus scanners, explosion-proof meters, and more!

We currently have over 2,900 instruments in stock and ready to ship now, so your panels will look great for the new year! And we have substantial printed circuit board assemblies and other parts to quickly build out of stock products.

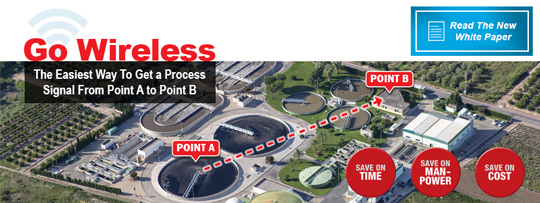

A major problem that often comes up in industrial automation, particularly when trying to upgrade existing systems, is simply finding a way to get a process signal from point A to point B in the most economical and efficient manner.

Running physical wires between devices can be costly and time consuming, especially when there is a need to run them through conduit or dig trenches over long distances. Facilities that have been in operation for a long time may have gone through many iterations of process control equipment, leaving behind a rat’s nest of old wires which makes running of new wires sometimes difficult. Often, it is simply less expensive and less time consuming to transmit the signal wirelessly.

See real life applications of how two wastewater plants used point to multi-point wireless systems to economically and efficiently transmit process signals wirelessly to a central location.

Programming and operation of the ProtEX-MAX is now easier and more reliable with the New CapTouch buttons. All PD8 series meters and controllers are equipped with four capacitive sensors that operate as through-glass buttons so that they can be operated without removing the cover (and exposing the electronics) in a hazardous area or harsh environment. CapTouch buttons are designed to protect against false triggering and can be disabled for security by selecting DISABLE on the switch labeled NO-CONTACT BUTTONS located on the connector board.

The PDA-LH series light/horn accessory can be connected to select Precision Digital meters to provide better visibility and control of alarm conditions. It is available in three different light configurations and each comes with a built-in 85 dB horn. Both the light and horn can be controlled independently of each other using separate relays on the meter, and may be reset in a variety of ways.

For panel meters housed in an enclosure and PD2/PD4 meters, the MOD-LH and MOD-PD2LH light/horn modification series are available. These provide a light/horn, a button that connects to the meter's digital input to control or reset alarms, and hole drilling on the enclosure for both the light/horn and button. Meters and enclosures are sold separately. Visit the links below for installation and compatibility details.

Precision Digital offers a large selection of digital panel meters for use in various process control applications. Choose from line or loop powered, single or dual line displays, and safe or hazardous area approved. Features available include a NEMA 4X / IP65 front panel, sunlight readable displays, extra-large digits, UL and C-UL listing, up to 8 relays, 4-20 mA outputs, and Modbus communications. For 50 years, customers have trusted Precision Digital panel meters to reliably display, control, and alarm critical process information.

In this application, a wastewater treatment facility needed to transmit process signals from the Secondary Inflow and Final Effluent to the base station at the Central Building where Primary Inflow is calculated and sent to an Auto-Sampler.

Digging trenches and running wires around the plant to get the 4-20 mA signals to where they needed them would have made this a bigger and more expensive project than they wanted, so they decided to use a wireless signal system which saved them a lot of time, man-power, and cost.

Read more to see how this wastewater facility used an economical and efficient point to multi-point wireless system to transmit the process signals.

Wireless Products

Precision Digital’s wireless products have been redesigned to add new features and improve the user experience. The field units are now housed in a larger enclosure to make field wiring easier and provide room for a two relays option module, a Loss of Signal (LoS) digital output is now available, and the units can be programmed with CapTouch Buttons. The base stations are now available to hold 2, 6, or 16 I/O modules and have Loss of Signal (LoS) capability as well as improved mechanical functionality.

The following bullet lists contain the new features highlighted in yellow:

PDW30 Point-to-Point Wireless Bridge

- Signal Wire Replacement Bridge

- Matched Pair of Wireless Field Units

- Virtually Plug and Play Right out of Box

- Range: 1 Mile Line-of-Sight Outdoor, 500 Feet Indoor

- Repeaters Available to Extend Range

- Wireless Transmission Between Primary and Secondary Unit of

• 4-20 mA (Separate Signals Going Both Ways)

• Discrete (4 Digital I/O Signals Going Both Ways)

• RS-485 Modbus - Inputs: 4-20 mA or 0-10 V (1), Discrete/Digital (up to 4), Modbus

- Outputs: 4-20 mA (1), Discrete/Digital (up to 4), Relays (2), Modbus

- Isolated RS-485 Modbus Communications

- Loss of Signal (LoS) Digital Output

- PDA10 Signal Strength Survey Tool to "Try Before You Buy"

- Field Installable Relay Module with Two Form A (SPST) 5A Relays (Available for Both Units)

- Configure Using PDW Manager Software and On-Board USB

- Backlit Display Provides Helpful Input & Output Information

- CapTouch Through-Glass Button Programming

- IP68, NEMA 4X Aluminum & Stainless Steel Enclosures

- Plenty of Room for Field Wiring

- Operating Temperature Range: -55 to 75°C (-67 to 167°F)

- Conformal Coated PCBs for Dust & Humidity Protection

- 9-30 VDC Power

PDW90 Point to Multi-Point Wireless System

- System Consisting of Wireless Base Station and Field Units

- Signal Wire Replacement for up to 32 4-20 mA Signals

- Range: 1 Mile Line-of-Sight Outdoor, 500 Feet Indoor

- Repeaters Available to Extend Range

- Wireless Transmission Between Base Station and any Field Unit of

• 4-20 mA (Separate Signals Going Both Ways)

• Discrete (4 Digital I/O Signals Going Both Ways)

• RS-485 Modbus - Inputs: 4-20 mA or 0-10 V (1), Discrete/Digital (up to 4), Modbus

- Outputs: 4-20 mA (1), Discrete/Digital (up to 4), Relays (2), Modbus

- Base Station I/O Modules for 4-20 mA Inputs, 4-20 mA Outputs, Relay Outputs, Digital I/O

- Base Stations for 2, 6, or 16 Field Installable I/O Modules & Modbus

- Loss of Signal (LoS) Digital Output

- PDA10 Signal Strength Survey Tool to "Try Before You Buy"

- PDW Manager Programming Software and On-Board USB

- Field Units Available in NEMA 4X Aluminum & Stainless Steel

- Field Unit Operating Temperature Range: -55 to 75°C (-67 to 167°F)

- PCBs are Conformal Coated for Dust & Humidity Protection

- Power: 9-30 VDC, Base Station & Field Units

Precision Digital’s PDW wireless products give you a simple, straightforward way to get analog, discrete, or Modbus® signals from where you have them to where you need them. Our wireless solutions range in complexity from simple point-to-point for wire replacement, to large-scale point-to-multipoint for connecting up to 32 individual field locations to a central base station. Wireless installations may be expanded or improved using an array of base station modules, additional wireless field units, and repeater units.

A major problem that often comes up in industrial automation, particularly when trying to upgrade existing systems, is simply finding a way to get a process signal from point A to point B in the most economical and efficient manner.

In this webinar, Joe Ryan, VP of Sales & Marketing, will review the contents in this newly released “Go Wireless” whitepaper written for people in the industrial process industry looking for an economical and efficient wireless solution for transmitting analog, discrete, and Modbus signals.

Joe will discuss the problems and solutions for upgrading existing systems and getting process signals from where you have them to where you want them.

- No trenches to dig, no long runs of costly wire, no rat’s nest of wires

- Save money by installing a PDW wireless system for analog, discrete, and Modbus signals

- See real life wastewater treatment plants’ implementation of PDW wireless systemss

Also in this webinar, Joe will show you a quick overview of Precision Digital’s PDW wireless products and illustrate two typical tank monitoring setups using a point-to-point wireless bridge, and a point to multi-point wireless system.