General

Display: Upper display: 0.60" (15 mm) high. Lower display: 0.46" (12 mm) high. Both are 6 digits (-99999 to 999999), red LEDs

Display Intensity: Eight user selectable intensity levels

Display Update Rate: 5/second (200 ms)

Overrange: Display flashes 999999

Underrange: Display flashes -99999

Display Assignment: The Upper and Lower displays may be assigned to process values for Channels A (Ch-A), B (Ch-B), or C (Ch-C), toggle between (Ch-A & Ch-B, Ch-A & Ch-C, Ch-B & Ch-C, and Ch-A, Ch-B, & Ch-C), toggle between Channel & units, show channel gross value (no tare) or toggle net (tare) and gross values, show relay set points, max & min values, or Modbus input. The second display may also be set to show engineering units or be off, with no display.

Front Panel: NEMA 4X, IP65

Programming Methods: Four front panel buttons, digital inputs, PC and MeterView Pro software, Modbus registers

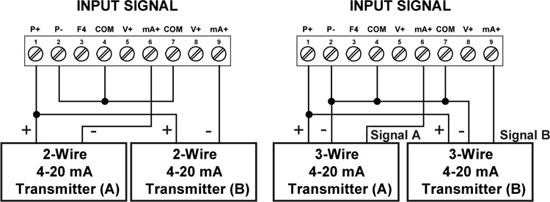

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels: Logic High: 3 to 5 VDC

Noise filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of calibrated span

Recalibration: All ranges are calibrated at the factory. Recalibration is recommended at least every 12 months.

Max/Min Display: Max (Peak) / min (Valley) readings reached by the process are stored until reset by the user or until power to the meter is cycled.

Password: Three programmable passwords restrict modification of programmed settings.

Non-Volatile Memory: All programmed settings are stored in non-volatile memory for a minimum of ten years if power is lost.

Power Options: 85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max, or optional model with 12-24 VDC ±10%, 15 W max.

Fuse: Required external fuse: UL Recognized, 5 A max, slow blow; up to 6 meters may share one 5 A fuse.

Isolated Transmitter Power Supply: Terminals P+ & P-: 24 VDC ± 10%. Internally selectable jumper for 24, 10, or 5 VDC supply.

85-265 VAC models rated @ 200 mA max, 12-24 VDC powered models rated @ 100 mA max, @ 50 mA max for 5 or 10 VDC supply.

Normal Mode Rejection: Greater than 60 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output or output-to-P+ supply.

Overvoltage Category: Installation Overvoltage Category II: Local level with smaller transient overvoltages than Installation Overvoltage Category III.

Environmental: Operating temperature range: -40 to 65°C

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Enclosure: 1/8 DIN, high impact plastic, UL 94V-0, color: black

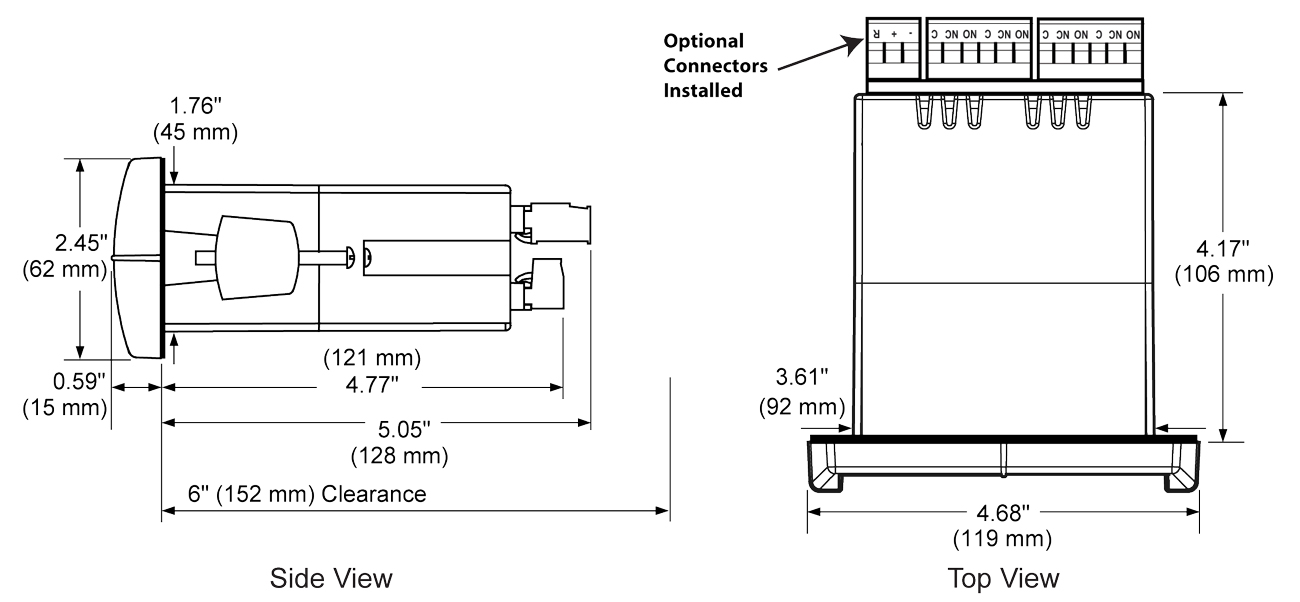

Mounting: 1/8 DIN panel cutout required: 3.622" x 1.772"

(92 mm x 45 mm). Two panel mounting bracket assemblies are provided.

Tightening Torque: Screw terminal connectors: 5 lb-in (0.56 Nm)

Overall Dimensions: 4.68" x 2.45" x 5.64"

(119 mm x 62 mm x 143 mm) (W x H x D)

Weight: 9.5 oz (269 g)

UL File Number: UL & c-UL Listed. E160849; 508 Industrial Control Equipment.

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant

Connector Type: Micro-B receptacle

Cable: USB A Male to Micro-B Cable

Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit, Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit

Power: USB Port

Dual Process Input

Inputs: Two non-isolated inputs, each separately field selectable:

0-20, 4-20 mA, 10 V (0-5, 1-5, 0-10 V), Modbus PV (Slave)

Channels: Channel A, Channel B, Channel C (Math channel)

Programmable Constants: Constant P (Adder): -99999 to 999999, default: 0.000; Constant F (Factor): 0.00001 to 999999, default: 1.000

Math Functions: Addition, difference, absolute difference, average, multiplication, division, max of A or B, min of A or B, draw, weighted average, ratio, concentration. See instruction manual for details.

Sequence of Operations for Input Programing:

- Select Input for A and B

- Set up the engineering units for A, B, and C

- Set up decimal point for A, B, and C

- Scale A & B

- Set up the displays for A, B, or C

- Select the transfer function for A & B (e.g. Linear)

- Select Math function for Channel C

- Program constants for Factor (F) and Adder (P).

- Program cutoff values for A and B

Accuracy: ±0.03% of calibrated span ±1 count, square root & programmable exponent accuracy range: 10-100% of calibrated span

Temperature Drift: 0.005% of calibrated span/°C max from 0 to 65°C ambient, 0.01% of calibrated span/°C max from -40 to 0°C ambient

Signal Input Conditioning: Linear, square root, programmable exponent, or round horizontal tank volume calculation.

Multi-Point Linearization: 2 to 32 points for channel A and B

Programmable Exponent: 1.0001 to 2.9999

Low-Flow Cutoff: 0-999999 (0 disables cutoff function)

Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd.

Calibration Range: 4-20 mA: minimum span input 1 & input 2: 0.15 mA. ±10 V: minimum span input 1 & 2: 0.10 V. An Error message will appear if input 1 and input 2 signals are too close together.

Input Impedance: Voltage ranges: greater than 500 kΩ. Current ranges: 50 - 100 Ω (depending on resettable fuse impedance).

Input Overload: Current input protected by resettable fuse, 30 VDC max. Fuse resets automatically after fault is removed.

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

Relays

Rating: 2 or 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 W) @ 125/250 VAC for inductive loads.

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

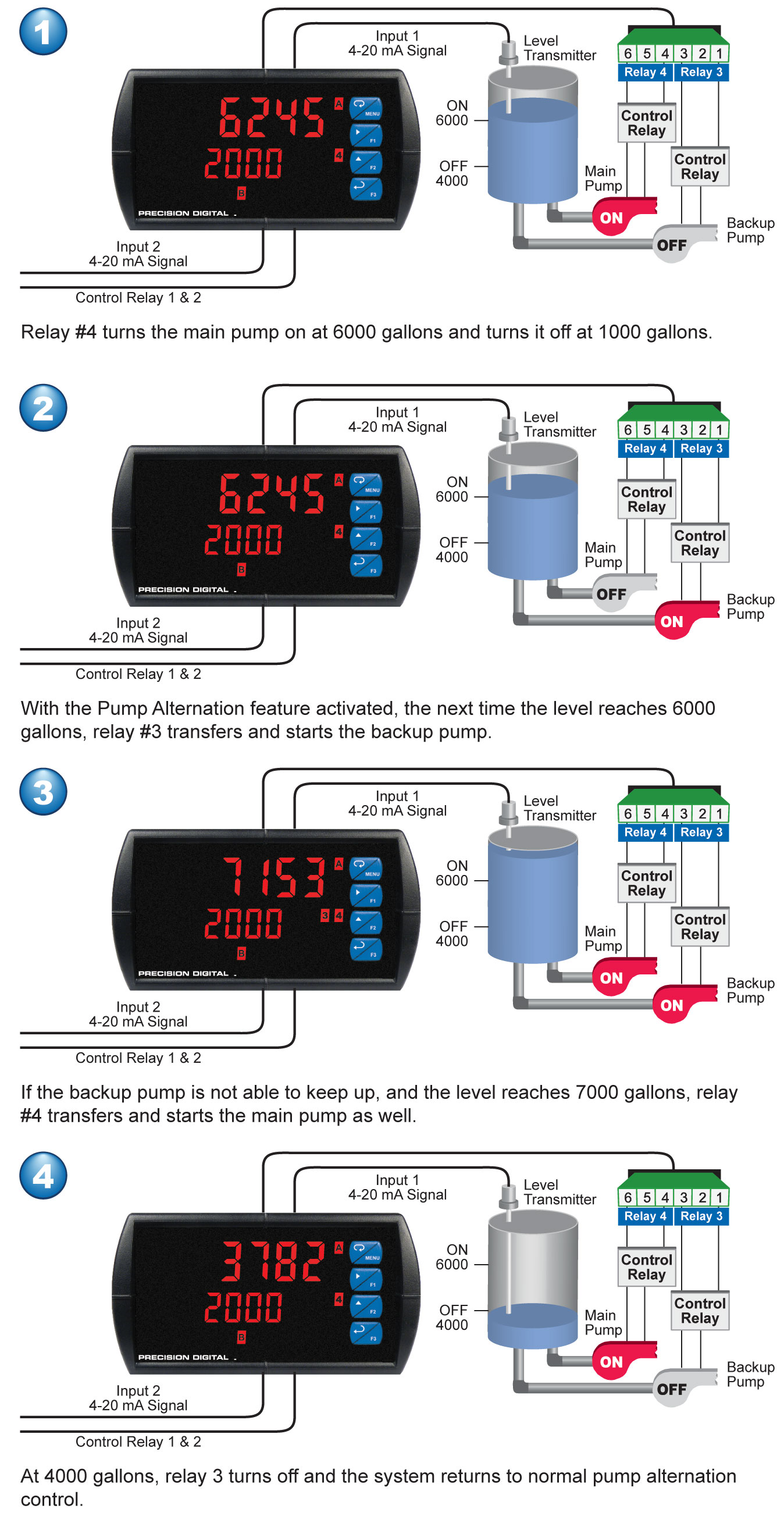

Relay Operation: automatic (non-latching), latching (requires manual acknowledge), sampling (based on time), pump alternation control (2 to 8 relays), Off (disable unused relays and enable interlock feature, manual on/off control mode).

Relay Reset: User selectable via front panel buttons or digital inputs.

- Automatic reset only (non-latching), when input passes the reset point.

- Automatic + manual reset at any time (non-latching).

- Manual reset only, at any time (latching).

- Manual reset only after alarm condition has cleared (latching).

Note: Front panel button or digital input may be assigned to acknowledge relays programmed for manual reset.

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay. Note: Relay coil is energized in non-alarm condition. In case of power failure, relay will go to alarm state.

Auto Initialization: When power is applied to the meter, relays will reflect the state of the input to the meter.

Serial Communications

Protocol: Modbus® RTU

Meter Address/Slave ID: 1 - 247

Baud Rate: 300 - 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 - 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Note: Refer to the ProVu Modbus Register Tables located at www.predig.com for details.

Isolated 4-20 mA Transmitter Output

Output Source: Process channel A, B, or C, max or min for channel A, B, or highest or lowest max or min of A and B, set points 1-8, Modbus input, or manual control mode

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated: 4.000 to 20.000 = 4-20 mA output

Analog Output Programming: 23.000 mA maximum for all parameters: Overrange, underrange, max, min, and break

Accuracy: ±0.1% of span ±0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µ/°C max from -40 to 0°C ambient

Note: Analog output drift is separate from input drift.

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All models rated @ 40 mA max.

External Loop Power Supply: 35 VDC maximum

Output Loop Resistance:

| Power supply | Minimum | Maximum |

| 24 VDC | 10Ω | 700Ω |

| 35 VDC (external) | 100Ω | 1200Ω |

Digital I/O Expansion Module

Channels: 4 digital inputs & 4 digital outputs per module

System: Up to 2 modules for a total of 8 inputs & 8 outputs

Digital Input Logic: High: 3 to 5 VDC Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC Low: 0 to 0.4 VDC

Source Current: 10 mA maximum

Sink Current: 1.5 mA minimum

+5 V Terminal: To be used as pull-up for digital inputs only.

4-Relay Expansion Module

Relays: Four Form A (SPST) rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈50 watts) @ 125/250 VAC for inductive loads.